Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic Testing Laboratory in Delhi/NCR

“Phased Array Ultrasonic Testing (PAUT) is an advanced non-destructive testing (NDT) technique used to inspect butt welded joints with exceptional precision. This method employs multiple ultrasonic beams that can be electronically controlled and steered to create detailed images of the weld area. PAUT allows for accurate flaw detection, sizing, and characterization, making it highly effective in assessing the integrity of butt welded joints.

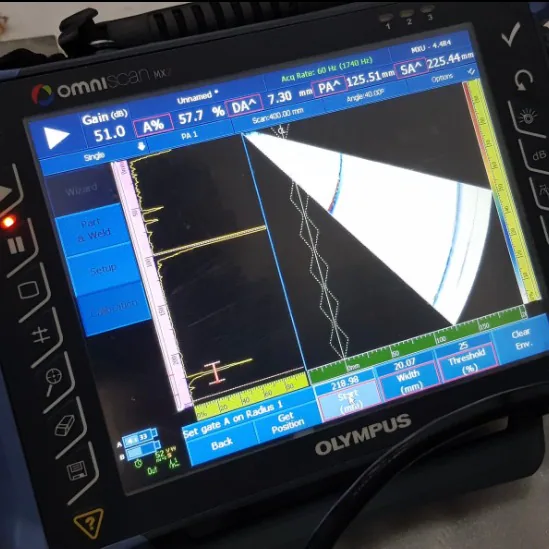

During a PAUT examination, the phased array probe emits ultrasonic waves at different angles, allowing the inspector to evaluate the weld’s internal structure and detect any defects or anomalies. The data collected is then processed using specialized software, enabling the inspector to create a comprehensive evaluation of the weld’s quality.

PAUT offers several advantages over conventional ultrasonic testing methods. The ability to control and steer the ultrasonic beams provides enhanced inspection coverage, reduced inspection time, and improved sensitivity to small defects. Moreover, PAUT is a safe and efficient technique that does not require direct contact with the welded surface, minimizing the risk of damage to the weld.

Inspection & Testing Engineers (ITE) is the leading organization for providing PAUT of butt welded joints. With extensive experience in the field of NDT, ITE has a proven track record of delivering reliable and accurate inspection results. Their team of certified and skilled technicians are proficient in utilizing PAUT technology to its fullest potential, ensuring thorough assessments of butt welded joints.

ITE’s investment in state-of-the-art PAUT equipment demonstrates their commitment to offering cutting-edge inspection services. This advanced technology allows for faster inspections and precise flaw detection, enhancing the overall efficiency of the inspection process.

Furthermore, ITE is known for its adherence to industry standards and safety protocols during their inspections. Clients can trust ITE to provide high-quality and compliant PAUT inspections, ensuring the integrity of butt welded joints and preventing potential failures.

In conclusion, Phased Array Ultrasonic Testing of butt welded joints is a valuable NDT method for assessing weld quality with unparalleled accuracy. Inspection & Testing Engineers (ITE) is the best organization to provide PAUT services due to their expertise, advanced equipment, commitment to safety, and track record of delivering reliable inspection results. With ITE’s PAUT inspections, clients can confidently maintain the integrity and safety of their butt welded joints, contributing to the success of their projects and operations.”