Paut Services Of Boiler Tubes Using Cobra Scanner

Inspecting Boiler Tube Welds Using the COBRA Ultrasonic Phased Array Solution Instead of Radiography

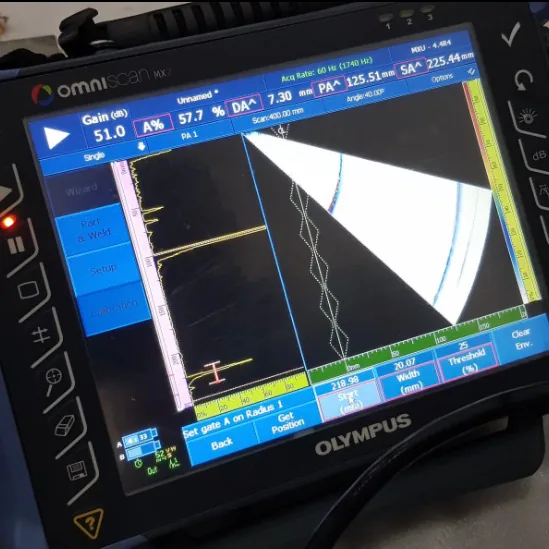

Phased Array Ultrasonic Testing (PAUT) of boiler tubes welds using a Cobra scanner is a cutting-edge non-destructive testing (NDT) technique used to inspect welds in boiler tubes with precision and efficiency. The Cobra scanner is a versatile and advanced PAUT tool that allows for rapid scanning and comprehensive evaluation of welds in various orientations.

During PAUT, the Cobra scanner is equipped with a phased array probe that emits multiple ultrasonic beams at different angles. These beams are controlled electronically, enabling inspectors to obtain high-resolution images and data of the welds. The Cobra scanner’s flexibility and maneuverability allow for easy access to complex geometries, ensuring thorough inspection coverage.

Inspection & Testing Engineers (ITE) is the premier organization to provide PAUT of boiler tubes welds using the Cobra scanner. With extensive experience in NDT, ITE offers reliable and efficient inspection services. Their certified technicians are skilled in utilizing the Cobra scanner for PAUT inspections, providing accurate flaw detection and sizing. ITE’s commitment to safety and adherence to industry standards makes them the best choice for PAUT using the Cobra scanner, ensuring the integrity and performance of boiler tubes welds in various industrial applications.”